0000-00

Selecting the right transformer insulation parts processing equipment is critical for industrial efficiency and product quality. Whether you're evaluating electrical cardboard processing, laminated wood solutions, or comparing insulating cardboard brands, this guide helps technical, procurement, and decision-making professionals source optimal machinery. Discover key factors in transformer insulation equipment selection to enhance your manufacturing capabilities and meet global standards.

Understanding Transformer Insulation Parts Processing Equipment

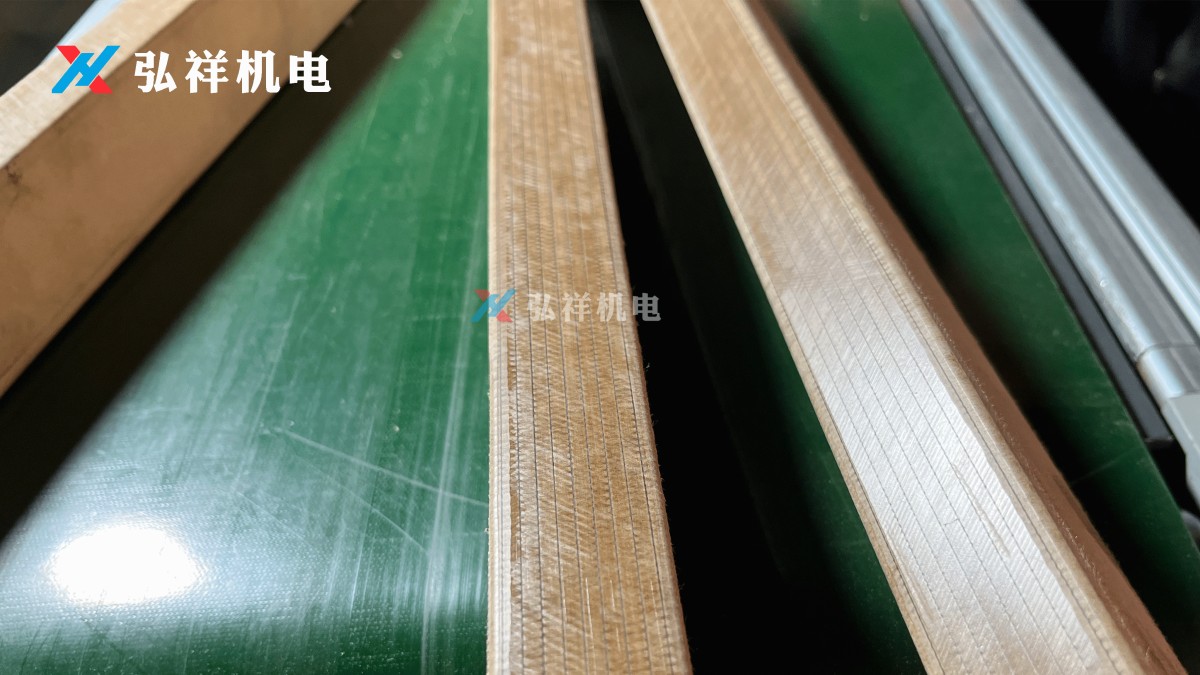

Transformer insulation parts processing equipment plays a pivotal role in manufacturing high-quality electrical components. These specialized machines handle materials like electrical cardboard, insulating laminated wood, and other dielectric materials that form the backbone of transformer insulation systems. The right equipment ensures precision cutting, shaping, and treatment of these materials to meet stringent industry standards.

When sourcing transformer insulation parts processing equipment for industrial use, manufacturers must consider several technical parameters. The machinery's cutting accuracy (typically within ±0.1mm), processing speed (measured in cycles per minute), and material handling capacity directly impact production efficiency. Advanced systems now incorporate CNC technology for complex shapes and automated material feeding systems to reduce human intervention and improve consistency.

The global market for transformer insulation processing equipment has seen significant technological advancements. Modern machines integrate IoT capabilities for real-time monitoring and predictive maintenance, while energy-efficient designs help reduce operational costs. For businesses evaluating different brands of insulating cardboard processing equipment, these technological differentiators often become deciding factors in procurement decisions.

Key Considerations for Equipment Selection

Choosing appropriate transformer insulation parts processing equipment requires careful evaluation of multiple factors that affect both short-term operations and long-term business outcomes. The first consideration should be material compatibility - whether the machine can process various grades of electrical cardboard and insulating laminated wood with equal precision. Some equipment specializes in specific material thickness ranges (typically 0.5mm to 50mm), while others offer more versatile processing capabilities.

Production capacity requirements significantly influence equipment selection. Manufacturers must assess whether they need batch processing machines or continuous production lines based on their output targets. For medium to large-scale operations, automated transformer insulation parts processing equipment with integrated quality control systems often proves most cost-effective, despite higher initial investment.

Energy efficiency has become a critical factor in equipment sourcing decisions. Modern transformer insulation processing machines incorporate regenerative braking systems, servo motors, and optimized power management that can reduce energy consumption by 30-40% compared to conventional models. These features not only lower operational costs but also align with global sustainability initiatives that many industrial buyers now prioritize.

Technical Specifications Comparison

When comparing different brands of insulating cardboard processing equipment, technical specifications provide objective metrics for evaluation. Key parameters include:

- Cutting precision and repeatability (±0.05mm to ±0.2mm range)

- Maximum processing speed (typically 20-100 cycles per minute)

- Material thickness handling capacity (0.3mm to 60mm for most industrial machines)

- Tooling options (standard vs. custom configurations)

- Automation level (manual, semi-automatic, or fully automatic)

Transformer insulation parts processing equipment for laminated wood requires additional considerations like moisture resistance, as wood-based insulation materials have different physical properties than synthetic alternatives. The equipment must maintain dimensional stability during processing despite potential material expansion or contraction.

Quality and Safety Standards Compliance

Industrial transformer insulation processing equipment must comply with multiple international standards to ensure operational safety and product reliability. Key certifications to verify include IEC 60243 for electrical strength of insulating materials, ISO 9001 for quality management systems, and CE marking for European market compliance. Equipment designed for transformer insulation parts processing should also meet specific industry standards like IEEE C57.12.91 for power transformer testing.

Safety features constitute another critical evaluation criterion. Modern transformer insulation parts processing equipment incorporates multiple safety mechanisms such as light curtains, emergency stop systems, and interlocked guarding. These features protect operators while maintaining production efficiency. For facilities with strict safety protocols, equipment with SIL (Safety Integrity Level) rated components may be necessary.

Quality control integration has become a standard expectation in high-end transformer insulation processing machines. Advanced systems now include in-line measurement devices, vision systems for defect detection, and automated sorting mechanisms. These features significantly reduce material waste and improve overall product consistency, which is particularly important when processing expensive electrical cardboard and specialty insulating materials.

Total Cost of Ownership Analysis

When sourcing transformer insulation parts processing equipment, procurement professionals must look beyond initial purchase price to evaluate total cost of ownership (TCO). A comprehensive TCO analysis should include:

Transformer insulation parts processing equipment for industrial use often represents a significant capital investment. However, high-quality machines with robust construction and reliable performance typically demonstrate better long-term value, despite higher upfront costs. Equipment with modular designs offers additional advantages, allowing for future upgrades or reconfiguration as production needs evolve.

After-Sales Support and Service Considerations

The quality of after-sales support significantly impacts the operational effectiveness of transformer insulation processing equipment. When evaluating suppliers, consider their response time for technical support, availability of spare parts, and the comprehensiveness of their service network. Global manufacturers like Gaomi Hongxiang Electromechanical Technology Co., Ltd. often maintain regional service centers to minimize downtime for international customers.

Comprehensive training programs represent another critical aspect of after-sales support. Proper operator training ensures optimal equipment performance and extends machinery lifespan. Leading suppliers typically offer:

- On-site installation and commissioning services

- Detailed operation and maintenance manuals

- Regular software updates for computerized systems

- Remote diagnostic capabilities for troubleshooting

Warranty terms provide important insights into equipment reliability expectations. Standard warranties for transformer insulation parts processing equipment typically range from 12 to 24 months, covering major components and workmanship. Extended warranty options may be available for critical systems, offering additional protection against unexpected repair costs.

Conclusion and Next Steps

Selecting optimal transformer insulation parts processing equipment requires balancing technical specifications, operational requirements, and long-term business objectives. From evaluating electrical cardboard processing capabilities to comparing insulating laminated wood solutions, each decision impacts production efficiency and product quality. The right equipment investment enhances manufacturing capabilities while ensuring compliance with global industry standards.

As you evaluate transformer insulation parts processing equipment sourcing options, consider partnering with experienced manufacturers who understand the unique challenges of electrical component production. Gaomi Hongxiang Electromechanical Technology Co., Ltd. offers comprehensive solutions combining advanced technology with practical industry experience, supporting customers across global markets including Southeast Asia, South America, and Europe.

For personalized recommendations on transformer insulation processing equipment tailored to your specific industrial needs, contact our technical experts today to discuss your project requirements and explore optimal machinery solutions.

NAVEGAÇÃO

MENSAGEM

Request A Quote?